When we recently wrote about looking at solder paste up close, we happened to mention that it has a shelf life— something that you might expect to be uncontroversial considering that there is an expiration date, printed right there on the jar.

But, our reader Trav commented

Very nice pics. What happens to solder paste when it expires? does it taste funny? Do the balls go flat?

I assume the paste rather gets runny and doesn’t hold the solder in place or it gets thick and won’t spread evenly.

I’ve heard of it expiring, but never knew how. I’ve had a tube of flux for 20 years now. When it gets too thick, I put in a couple drops of alcohol and it seems to work good as new.

We like the “balls go flat” theory! But seriously, we presume that they wouldn’t label paste with a short shelf life— typically 4-12 months, when kept refrigerated, depending on the type of paste —unless there were a reason (and hopefully, a good reason) to do so.

A blog post on the Indium Corporation web site offers a little insight. It turns out that the “activator” chemicals within the flux, which serve to clean oxides off of the surfaces that will be soldered, also interact with the microscopic solder balls, gradually scouring off their surface oxides. When the solder particles are clean enough, they can actually cold-weld together, resulting in increased effective grain size and viscosity. As Trav notes, adding a little alcohol can reduce the viscosity of flux, but we can see how increased grain size and other factors (such as having used up some of the activators) could affect performance in other ways.

But in any case, it sounds like there are a range of experiences out there, and we would like to open the question for discussion: What has your experience been with out-of-date solder paste? Has it worked just fine? And if not, what was the failure mode?

Separately, what about (flux-cored) solder wire?

Kester has this to say, in their policy about shelf life:

Flux cored solder wire has a limited shelf life determined by the alloy used in the wire. For alloys containing more than 70% lead, the shelf life is two years from date of manufacture. Other alloys have a shelf life of three years from date of manufacture.

So, our spool of lead-free solder pictured above, with date of manufacture 3/16/05 expired five years ago in 2008. Presumably one reason for a stated expiration date is that the flux becomes less active over time as it interacts with the solder metal.

But in our personal experience, this kind of solder seems to generally work just fine, even many years past its nominal shelf life.

Many others seem to have had a similar experience with solder wire.

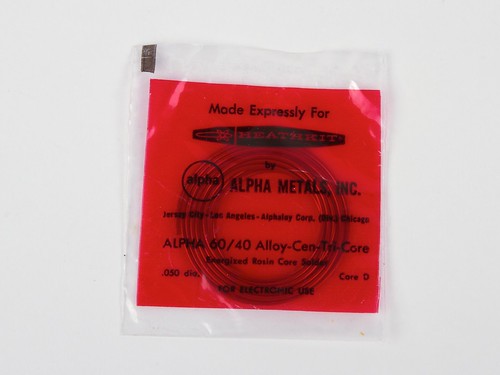

When we wrote about assembling a vintage Heathkit, we mentioned that it came with solder. It actually came with two little packets of solder, specifically 60/40 rosin-core, cheerfully labeled “Made Expressly For Heathkit by Alpha Metals, Inc.”

Seeing as (1) the kit and solder date back nearly 40 years, (2) Alpha Metals also uses the three-year figure for shelf life, and (3) we already had a fresh, open spool of Alpha Metals 60/40 rosin-core solder in the lab, we opted to use the fresh spool and save the vintage solder packets for a rainy day. Were we wrong to do so? Certainly, some of our readers thought so:

Solder shelf life? Are you sure about that? Solder paste has a shelf life but I’ve never heard of a shelf life for a real coil of 60/40 rosin core solder. I’ve used some pretty old stuff myself, a quick Google search for solder shelf life found me a discussion where a guy is talking about using solder from the 60s with no problem on the first click!

So what has your experience been? Have you used “old” solder, and if so, how well did it work?

if you keep solder wire dry it can last for years, store it in a damp enviroment and it’ll go bad in a matter of days. nothing as much fun as the moisture in the resin boiling making the tin jump all over the place.

I have a spool of Kester solder I bought in 1968 that still works great.

well, fwiw, I picked up a 1lb spool of solder about 29 years ago, and it’s still going strong… I recently put together 12 of the interactive led panels with it. I figure, some day, I might have to get more.

Good question! If you’re willing to sacrifice the vintage Heathkit stuff, you’d have a perfect side-by-side test.

When my oldest brother was a teen he spent some time teaching himself electronics. Around twenty years later I found his stash and decided to teach myself. In hindsight it was a pretty horrible set to teach myself with, but it had the distinct advantage of being free. It had a real soldering gun, which impressed me as a teen, but put out too much heat to solder anything more delicate than lamp cord. It also had the remains of a roll of 1/8″ flux core solder. (Lead of course.) The last time it had been used (~20 years previous) it hadn’t been sealed — the flux core was open to the air. About a foot of it had dried up and evaporated. I didn’t know what I was doing so I didn’t notice at the time, but kept cursing because the solder wouldn’t stick to anything. Eventually I used the roll down to where the good solder lived and it started to flow properly, but it was a frustrating way to learn to solder. The outside of the solder was pretty corroded, a fuzzy matte gray, but it heated and flowed like anything else with fresher rosin.

To this day, whenever I solder with larger gauge solder I make sure the tip of the solder tube is closed before putting it away. I figure it will be good for another 20+ years that way.

I’m working on a roll of solder that I’m pretty sure I’ve had since high school (1960s.) I haven’t noticed any problems, but maybe I should A-B it with some new (I want to say “modern”) solder.

Thanks for the reply. Those are some interesting thoughts. I may just have to do some experimenting myself.

I have SN/PB solder I purchased in the ’90s that I still use to this day for the difficult to solder connections that the Pb-free have a difficult time with and for rework. I have noticed no degradation in performance.

I only recently got into electronics, and inherited my dad’s solder – a decade-and-a-half-or-so old, flux-infused spool (similar to the one in the second pic in the article). It was stored in a normal environment in terms of temperature and humidity (not exceedingly dry nor overwhelmingly humid, just like the rest of the house), and works like a charm.

At my previous job I worked in electronics assembly and yes, using new solder works a little better. I won’t throw away the old stuff I have at home though. Using a clean iron, clean pcb and clean components is far more important as age of the solder.

It could be that the expiration date is necessary for certain applications, applications under certain circumstances, in certain environments or specific, highly regulated industries. It could also be that one large solder wire customer had a failure, at some point, and scientifically tested the cause. In this instance, if the age of the solder was even merely suspected as a cause, someone like Dow Chemical could demand “fresh”, resulting in a change over an entire vendor industry. In this case, however, I would suspect the marine industry. Assuming you’re not making supplies for the military or a biggie, like Dow Chemical, or are not soldering some sort of critical system for the marine industry, chances are it is not an issue.

I didn’t mean to imply that Dow Chemical uses a lot of solder. I’m just saying that a large buyer can change the way a supplier’s industry operates or even manufactures. It could have been a Dow vendor that got called to the carpet for solder failure and a single vendor used it as an excuse. A huge buyer can change the way other industries do things. Dow is just the hugest I could think of and in the manufacturing arena, it has a great deal of influence because it likes small vendors. A monster like Dow Chemical – or Intel or whatever – can’t turn on a dime. Even a small change must go through many “committees” and can take years to implement. Having small vendors who CAN turn on a dime is critical to their operations.

Old solder might be perfectly “usable,” but try using a 10 year old spool and a brand new spool one after the other on a small-pitch SMD part, and tell me that there isn’t a big difference!

After noticing this for the first time, I never buy more solder than I can use in a couple years.

At work we are required to throw out “expired” solder and solder paste. It is a liability problem, the FAA hates to find expired chemicals and uncalibrated equipment on their inspections. At home I have used twenty year old rolls. My stuff at home is just for my use and no ones life is at risk.

My big spool of Radio Shack 60/40 from the mid-1970’s still works fine, and even smells the same. (Mostly through-hole, not fine-pitch SMD. Hobby, not FAA.)

Just recently used up a spool of my father’s early-1960’s-era solder from Lafayette Radio Electronics, and now I’m working on a later-60’s spool labeled “Archer” (a Radio Shack house brand).

There might be some reason new solder is better for something, but I’ve not had any troubles doing standard PCB and parts soldering.

I still have a most of a 1 lb. spool of solder that I bought about 40 years ago to build some Heathkit projects. It’s lost its label, but I remember that it was “multicore” rosin core solder for electronics; I assume it’s 60/40. I used it last year to build a small kit (LED Menorah) and it seemed to worked for me, although if you look at my solder joints, it’s clear that I need more practice. I did cut about 6 inches off the end before I used it. It’s a bit coarse (0.05 inch), so I picked up some new 63/37 solder (just a pocket pack this time) which I used for another LED menorah kit. The joints on the new kit don’t look much better, so I expect it’s my skill more than the solder that need upgrading.

I have a 30 yr old spool of solder which works fine..and a little metal tin of flux that my Dad bought in the 1960s…I still use it.

I still use a 500g spool of Sn40Pb60 (RoHS be damned), stored for a large part of the last 10 years in a rather moist basement, compared with new (and hopefully correctly stored by the vendor) solder, there’s no noticeable difference.

This conversation has turned into an excellent reference. Well done!