Today we are relaunching the CandyFab Project with a new logo and a new wiki site, wiki.candyfab.org.

But more importantly, we are unveiling this new machine, the CandyFab 6000:

It’s a brand new CandyFab– still in beta. A clean break, designed from the ground up with almost no parts in common with the original, the CandyFab 4000. All new mechanics. All new electronics. All new software. Smaller but still big: the build volume is more than 10 liters, but it’s now small enough to fit on a desk top.

Here’s one of the first objects that we fabbed on the CandyFab 6000: a drilled sphere, about two inches in diameter and layer thickness of 1/15 inch. There’s plenty of room for improvement, and finally we have a machine that can be improved.

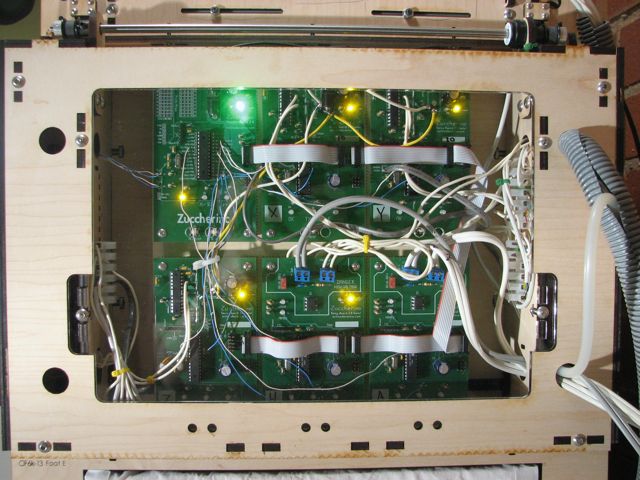

The machine is designed so that it can be made from scratch– i.e., without dumpster diving for old HP pen plotters. Three axes of quadrature-encoded DC servo motor control. Timing belts and acme lead screws. Food-safe sugar containment. The body is made from laser-cut plywood with acrylic highlights and stainless steel hardware. (Steampunk-compliant brass thumbscrews where appropriate, too.)

The new modular electronics control platform is called Zuccherino— that’s italian for “Sugar cube.” One Arduino-compatible circuit board per axis. (Our prototype above shows X,Y,Z, Heat, and Air axes, plus a master board.)

It’s an expandable system for all kinds of motion control projects, and we’ll be making kit versions of all of the Zuccherino boards later this summer.

We’ve also got new cross platform control software — called CandyFabulous underway, and it’s looking sweet.

And… oh can it fab sugar. In the photo here we’re partway through printing an hollow torus eight inches in diameter.

Where from here? Check out more details at CandyFab Project.

Finally, you can see the CandyFab 6000 first hand– this weekend at Maker Faire! We’ll be showing it off at booth #293, in the Expo Hall.

You people are my heroes.

You do realize, with that new logo, you’re going to have to figure out how to print in two different colors of sugar, right? Hm… I guess you could rig up a second head next to the heater, with a food coloring ink jet.

Excellent work – the new machine looks fabulous! I was wondering if there were any more developments in candyland, since there hadn’t been much in terms of updates on candyfab.org lately. Looking forward to seeing the new beast in person at Maker Faire!

Simply beyond belief! The CF4K was amazing already, this is at least 2000 more units of amazing!

I only wish I could be there to see it in person.

-Tom A

Congratulations! It looks awesome and I can’t wait to see it in action on Saturday. How big is it?

-Rob Cockerham

It’s about 24" wide, for scale.

—

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

Absolutely beautiful! I can see a Food Network special in your future.

Well… actually the Italian for "sugar cube" is "zolletta", not "zuccherino".

Zuccherini, as a noun, are little sugar candies… ;)

Anyway, this is the weirdest project i’ve ever seen.

I LOVE it! :D

M

(oh, btw, case sensitive captchas should avoid the letter "o" ;))

Why not correct all of the online italian-english dictionaries first– Why start here?

—

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

So, how does the resolution on the new 6000 model compare to the 4000. From the image it looks like the 4000 could do finer work.

The 6000, in our first test objects, is already comparable to the best that we ever saw from the 4000. As we said, the big difference is that this machine *can* be improved. The 4000 was at its limit– the 6000 is just getting started.

—

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

Awesome!

Great Job!

I saw the first iteration at TechShop in menlo park it was awesome then; it is that much more awesome now! props to you and your team! Hope to see you guys and gals at the maker faire!

Leo

One thing I haven’t seen so far in all the documentation on the candyfabs (maybe I just missed it).. Is, How is the new layer of sugar layed down? is it automated? or do you have to come along and manually add a new layer each time?

It’s *partially* automated– see the CandyFab FAQ. We’re still in early beta here– When we get the machine fast enough that switching layers is a pain, we’ll build a sugar-dispensing hopper that sits on the top.

—

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

why melt the sugar? Why not use a gentle spray of sugar frosting to stick the sugar grains together… that way, you could have much finer control and you wouldn’t get the blasting from the hot air blowing the stuff around.

A "gentle spray of sugar frosting"? Not sure what that would mean. You can lay down stripes of frosting– which would work okay. You could spray *water* to stick the sugar together, but I’m not sure what kind of frosting can be sprayed.

Hot air *FUSES* the sugar together without any binders. That’s the magic trick. The resulting product is not squishy wet candy (e.g., Jolly Rancher)– it’s closer to rock candy in consistency– dry and hard.

—

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

Absolutly amazing! It really is better than the original.

I have another silly idea to add to yours: Use a gian vat of uncooked egg, and spot cook with your heater to make it turn solid. Hopefully someone can add to my idea and suggest a medium that doesn’t start to smell so quickly.

Y’all made one hellova great machine!

Dave

Wonka would be proud.

That’s an hell of a machine. You must be an happy scientist after taking an hard look at what you’ve accomplished.

You’re amazing, guys!

where is the video? Where’s your yourtube?

This is awesome. I saw the old version a while back…

Great to see what you guys are doing. I can’t wait to see future improvements & what else this leads to.

Open Source RP = simply awesome.

Excites me so much I’m blogging about you. :)

-katie

http://katiepoterala.blogspot.com/

I wonder if you could use one of your sugar creations as a substitute for the wax in lost wax metal casting. It seems like it would work the same. (Maybe a little more sticky)

It’s possible. Might be better to put wax powder in the machine and fab that instead, if you want to do lost wax, though.

—

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

You need to fab a sugar Klein Bottle.

NEED TO.

Someone build the exact same concept using solar heat and sand instead of sugar. Quite impressive – and I had to immediately think of the candyfab :)

http://thisiscolossal.com/2011/06/markus-kayser-builds-a-solar-powered-3d-printer-that-prints-glass-from-sand-and-a-sun-powered-laser-cutter/