We’re here in New York for the 2011 Maker Faire New York (the “World Maker Faire”), held for the second year at the– absolutely fantastic —New York Hall of Science.

This weekend, we’ll be showing off an all-new prototype version of the Digi-Comp II. Back in May, at the Bay Area Maker Faire, we showed off a giant-scale version of the Digi-Comp II, documented here on our blog both in photos and with video.

Our new prototype is at the scale of the original (mid 1960’s) Digi-Comp II, which used half-inch diameter glass marbles. Rather than marbles, we’ve opted for half-inch diameter chrome steel balls–miniature pinballs or overgrown pachinko balls, depending on your perspective. The original machine was made of thin vacuum-formed plastic, supported by a sheet of masonite and fitted with injection-molded flip-flops and switches. While our final version will be fabricated from (very sturdy) vacuum-formed plastic, we’re currently in a phase of functional testing, using CNC-machined wooden versions.

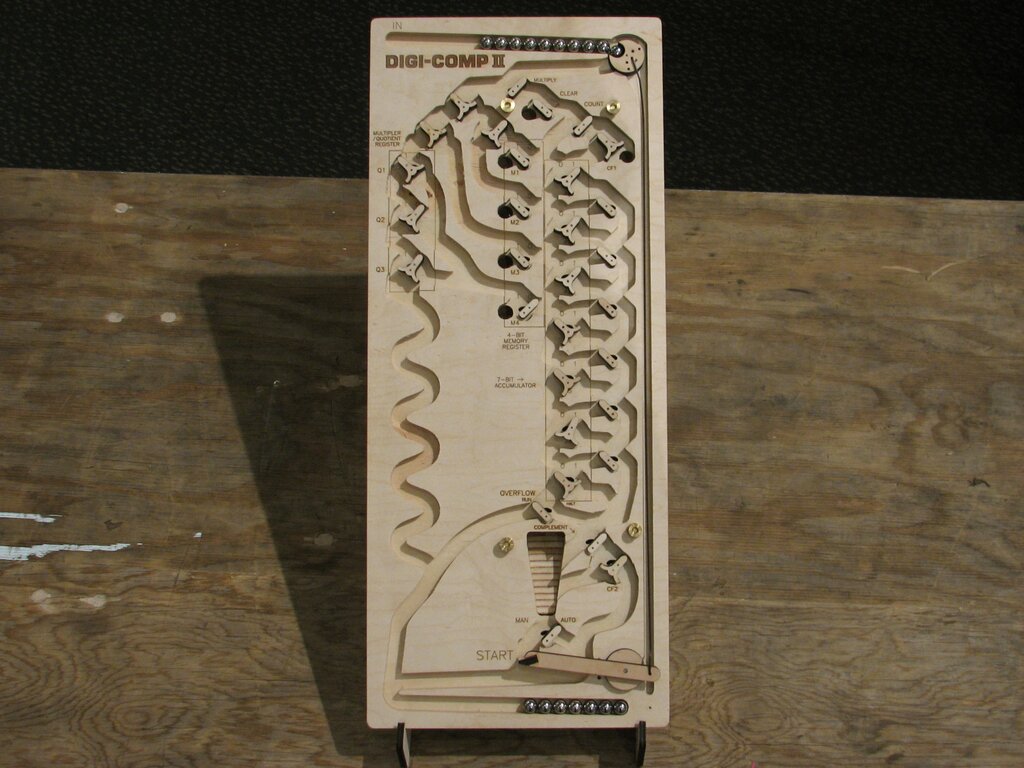

Here is what the whole machine looks like. Despite using the same size ball, the overall size is a bit smaller than the original: 10×24″ versus 14×28.5″. From testing, it’s clear that there are some places that a little more vertical room would make for a more user-friendly design, so it is likely that our final version will be closer to 25-26″ in length.

We’re here in New York for the 2011 Maker Faire New York (the “World Maker Faire”), held for the second year at the– absolutely fantastic —New York Hall of Science.

This weekend, we’ll be showing off an all-new prototype version of the Digi-Comp II. Back in May, at the Bay Area Maker Faire, we showed off a giant-scale version of the Digi-Comp II, documented here on our blog both in photos and with video.

Our new prototype is at the scale of the original (mid 1960’s) Digi-Comp II, which used half-inch diameter glass marbles. Rather than marbles, we’ve opted for half-inch diameter chrome steel balls–miniature pinballs or overgrown pachinko balls, depending on your perspective. The original machine was made of thin vacuum-formed plastic, supported by a sheet of masonite and fitted with injection-molded flip-flops and switches. While our final version will be fabricated from (very sturdy) vacuum-formed plastic, we’re currently in a phase of functional testing, using CNC-machined wooden versions.

Here is what the whole machine looks like. Despite using the same size ball, the overall size is a bit smaller than the original: 10×24″ versus 14×28.5″. From testing, it’s clear that there are some places that a little more vertical room would make for a more user-friendly design, so it is likely that our final version will be closer to 25-26″ in length.

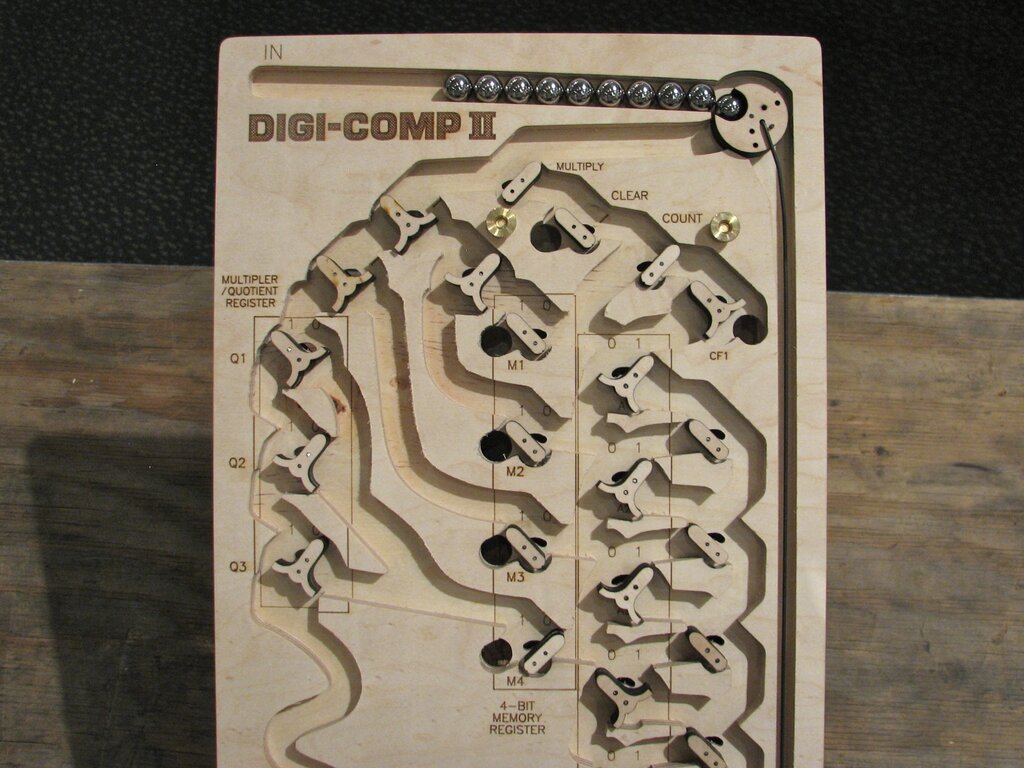

The top surface of the machine is cut from 1/2″ thick plywood, using a CNC router to make 3/8″ deep channels where the balls can roll. After routing, we added all of the labels by laser engraving. The flip-flops and switches are laser cut from thinner plywood, and rotate on simple plain bearings consisting of 1/16″ diameter stainless steel pins and slightly larger holes drilled through the wood. At the upper right, you can see the ball-release mechanism, which releases a ball when the actuated by the pushrod.

As with our giant model, the design is a functional but not exact replica of the original. All of the flip-flops, registers, and switches are approximately in the original locations, but the “wiring” (really, rolling ball paths) has been created from scratch. One of the non-obvious things when you first look at the Digi-Comp II is that there are actually two levels to the machine. The six “black holes” that you can see above drop the ball down to the lower level, as a shortcut to the bottom or (for certain functions) to flip switches on the top side.

The top surface of the machine is cut from 1/2″ thick plywood, using a CNC router to make 3/8″ deep channels where the balls can roll. After routing, we added all of the labels by laser engraving. The flip-flops and switches are laser cut from thinner plywood, and rotate on simple plain bearings consisting of 1/16″ diameter stainless steel pins and slightly larger holes drilled through the wood. At the upper right, you can see the ball-release mechanism, which releases a ball when the actuated by the pushrod.

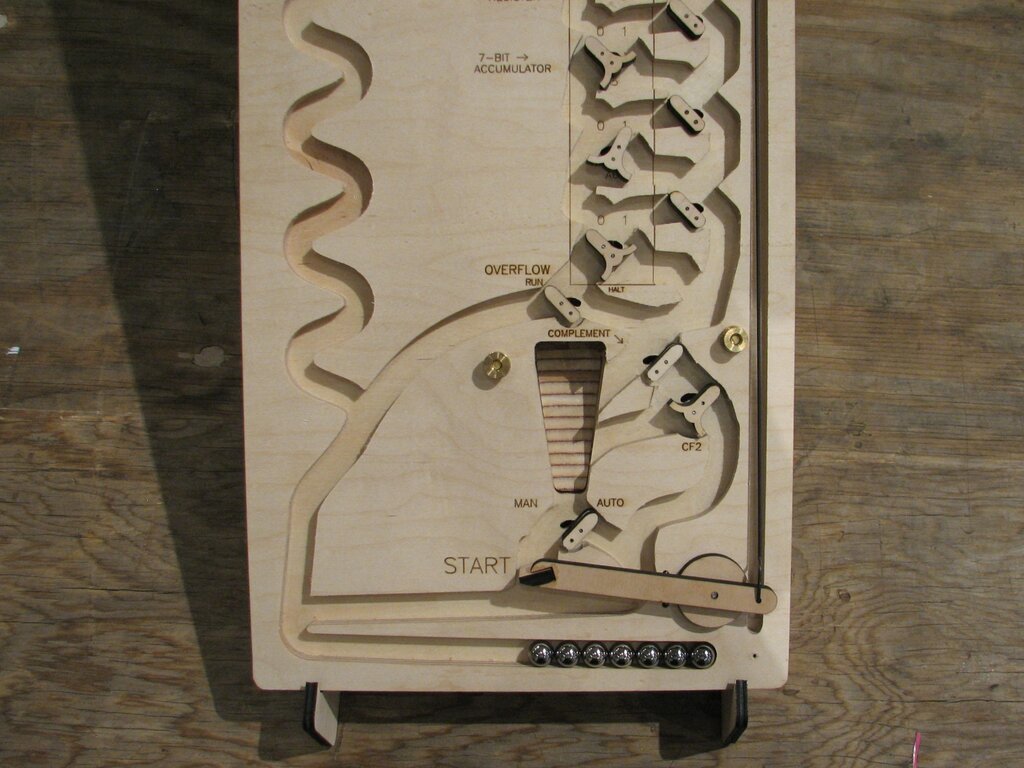

As with our giant model, the design is a functional but not exact replica of the original. All of the flip-flops, registers, and switches are approximately in the original locations, but the “wiring” (really, rolling ball paths) has been created from scratch. One of the non-obvious things when you first look at the Digi-Comp II is that there are actually two levels to the machine. The six “black holes” that you can see above drop the ball down to the lower level, as a shortcut to the bottom or (for certain functions) to flip switches on the top side. On the bottom half of the machine you can see the ball return as the stripy ramp in the center. The stripes on the ramp arise from cutting plywood at an angle (see here for another example). Below that is the Start Lever. When a ball presses down the start lever, it pushes the pushrod that releases the next ball from the top.

On the bottom half of the machine you can see the ball return as the stripy ramp in the center. The stripes on the ramp arise from cutting plywood at an angle (see here for another example). Below that is the Start Lever. When a ball presses down the start lever, it pushes the pushrod that releases the next ball from the top.We’ll be demonstrating our prototype Digi-Comp II all weekend at Maker Faire. If you’re in the area, please drop come see the Maker Faire, say hi, and try it out!

- Additional resources:

- If you’d like more information about the Digi-Comp II in general, please take a look at our prior articles (again, with photos and with video).

- The official site for our project is digicompii.com

- If you are interested in the forthcoming kit version, please sign up for the Evil Mad Science Mailing List.

I think it would be far cooler if the final version was made of plywood. CNC machined wood is awesome.

But I can understand going for plastic. Cheaper, lasts better.

We may offer a "deluxe" version made from CNC routed wood (or other materials), but it’s also important for us to be able to offer a lower cost version. :)

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

[I am not the same "Anonymous" as the one who posted the original comment]

Though I realize that it is late in the production process, let me just say that I agree with the original comment, and I, for one, would be more than willing to pay a little (or even a lot) extra for a wooden product. Again, I realize that it may be to late to change anything, just throwing my two cents in.

From your giant Digi-Comp II article, posted on 8th June, to this more modestly sized design, you’ve gone from a die-size of around 30,000cm^2 to around 1500cm^2.

If I’ve got my maths right, that’s a halving in surface area every 23 days or so.

You’re well ahead of Moore’s Law here!

I apologize for an off topic post, but do you happen to know what the rockets are behind the Maker Fair sign?

Gemini Titan II and Mercury-Atlas D. There’s more information here.

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

Great, thanks for the link.

I was surprised at how unpleasant the two men in your booth were to (well-behaved) kids at Maker Faire. Maybe it’s just your "evil mad" persona, but it wasn’t friendly at all.

I don’t know when you stopped by the booth, but we spent two days teaching many hundreds of kids about old computers and binary math. During that time, and as one might expect, we had four or five kids plus (very surprisingly) one old man, who came right up and started violently grabbing at the machine–to the point that we genuinely thought that it was going to break. We were appropriately firm with them, and in each case remained so for the duration that they remained at our booth, as long as about ten minutes in some cases. Perhaps you would have handled the situation differently, but I think that any reasonable observer who saw the entire interaction would consider our response moderate and far from that of unkind people. If you had come at a different time or stayed a little longer, you likely would have come away with a very different opinion of us.

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

We must have caught you at a bad moment, because you (not YOU – someone else in your booth) weren’t so pleasant to well-behaved, not-grabby kids when I was watching.

There weren’t two other men in the booth, and the primary complaint that we get at events is "not being evil enough." It would have been considerate of you to pull me aside and ask what was going on, rather than to assume the worst, and leave an anonymous comment about it.

Windell H. Oskay

drwho(at)evilmadscientist.com

http://www.evilmadscientist.com/

That looks like a gorgeous prototype, guys!

When you’re done, can you post the CNC code or models you used for the small wood version? I’d love to be able to make a polished one to live at our hackerspace.

-Gav

Sweet! I want one.

Is it Spring of 2012 yet?

Are you able to say about what this will cost? At least approximately?

Did I mention I want one? Sweet!