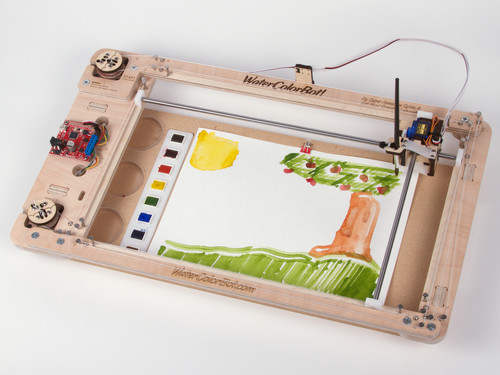

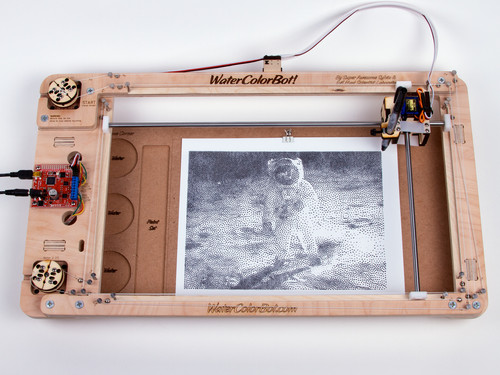

What goes into making a WaterColorBot? A lot, it turns out.

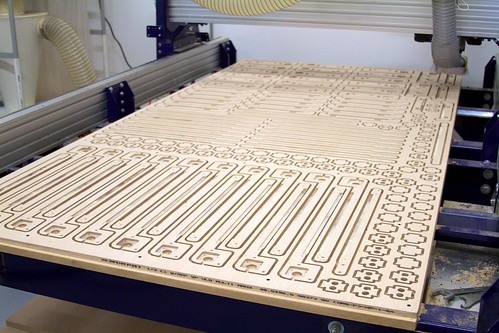

It all starts with a 4×8 foot sheet of Oregon-made maple-faced hardwood plywood. We mount the sheet on CNC router for a process that involves five tools (ranging from 0.086″ to .375″ in diameter) and about 2 1/2 hours of cutting time. We can fit 20 WaterColorBot frames, complete with their feet, on a single sheet of wood — efficiently tiled with very little waste. It’s also time efficient: Just under 8 minutes per frame.

The parts are held into the sheet by little tabs, so that they don’t go flying out during the machining process. We chisel them out of the sheet and inspect them prior to sanding. At this point the parts are carefully shaped and detailed but still rough to the touch around the edges.

Next up, sanding. Sanding removes the tabs and smooths the edges and surfaces to the touch. We use a combination of belt, disc, handheld power sander, and hand sanding for the various surfaces. All told, sanding all of the parts takes a little more than than twice as long as it does to cut them out of the sheet. (That might sound backwards until you watch how fast a CNC router moves compared to a human operating a sander.)

After sanding, the parts are clean and smooth, ready for engraving.

A special jig holds the four frame pieces in the laser for engraving. There are two passes, one for the primary markings, and one for the defocussed (blurry, dark) “WaterColorBot!” title text. We also engrave the back side of the top pieces (with a separate jig) with credits and the serial number.

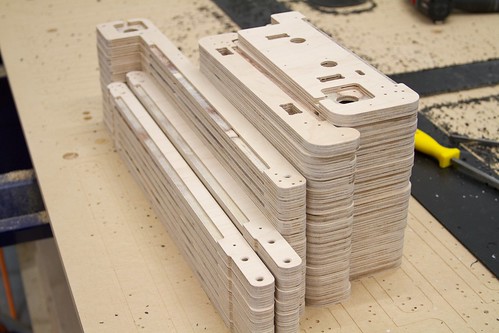

Stacks and stacks of WaterColorBot frame parts, before and after engraving.

The surfaces of the WaterColorBot are covered with a number of stainless steel rivets — either bare or with a ball bearing –that guide the Spectra cord around the frame as pulleys. We individually press-fit them into place with a small 1/2 ton arbor press.

The arrays of the four frame pieces– CNC cut, sanded, laser-engraved, and with their rivets press-fit — are now ready for assembly.

We use another specialized jig to hold the four frame pieces rigidly in place while screwing them together with a torque-limited electric screwdriver.

There are two types of “feet” that get mounted to the frame. The two left feet (always a fun term to use!) have holes in them to route the motor wires, while the two right feet do not. The feet are attached with wood glue, with the help of (yet) another specialized jig.

After that, we mount the back-side cable guide support, and queue the frames up for having their motors attached and final inspection.

The lower-deck pieces (“spoilboards”) are cut from 3/8″ MDF on the CNC router, in a much, much simpler process. They too are sanded and laser engraved, prior to having their paper clips mounted and being queued for inspection and shipping.

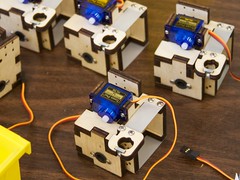

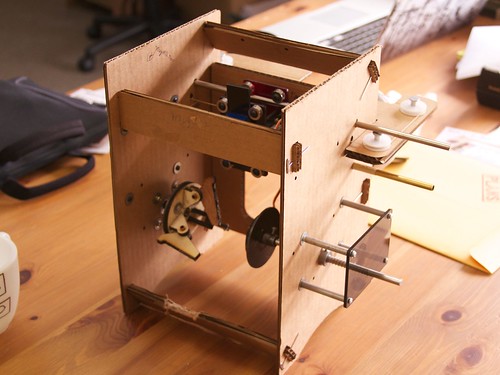

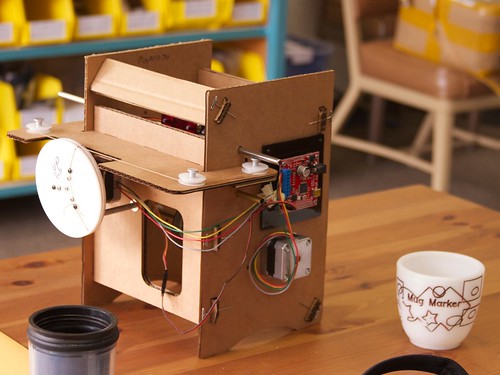

Next up: The WaterColorBot carriage. The base of the carriage consists of six pieces of laser-cut 1/4″ plywood. We found a very fast process of attaching these together, which is to clamp the box together with two perpendicular sets of thumbscrews and thumb-nuts (color coded as you see), and to wick in cyanoacrylate (super glue) between the surfaces at a few key points. It takes only a minute to assemble one; much faster than we were able to do with fasteners or wood glue.

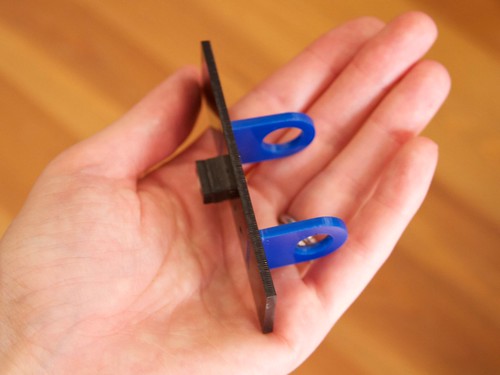

After mechanically drilling pilot holes to mount the servo motor, we assemble the rest of the carriage: Four bushings, two flexures that form the vertical linear stage, the servo motor, and the brush holder.

And then finally the 36″ servo extension cable and a laser-cut delrin cable guide, that prevents the cable from dragging on the paper. All neat and tidy.

The winch is also assembled from laser-cut wooden parts. The lower part has the shaft collar that mounts to the motor shaft, and the upper part has two halves that disassemble for cord management. It turns out that the winding-drum part of the winch needs to be quite round and concentric with the motor shaft for smooth operation– smoother than we can get with the laser. We solve this with our very-most-complicated assembly jig, which we’ll write about separately, if there’s interest.

In the kit, the winches come pre-wound with the appropriate length of 100 pound Spectra cord. We actually use an Eggbot as our tool to wind the cord. We mount the “spool” to one of the Eggbot stepper motors, and spin that motor (very quickly) for a set number of full revolutions to wind a fixed amount of cord onto each winch, using a modified version of the WaterColorBot software. Each winch is wound with about 125 inches of cord, in just nine seconds.

A box full of wound winches, ready to be added to our accessory bags.

The steel shafts that move the carriage came as 3 foot long rods, in a wooden crate the size of a coffin. We sent them to a local machine shop to be cut to length, after which they looked much neater.

We ended up purchasing four hundred sets of Crayola Washable Watercolors. After we received our giant drop shipment from Crayola– which was unreasonably fun, in a grade-school sort of a way –we stacked them all on the table to take a photo.

The paints, along with most of the other WaterColorBot accessories– wound winches, water dropper, velcro straps, power supply, and USB cable –get packed up in a pouch that will go in the shipping box.

Our “getting started” booklets — printed and stapled. (We’ll be talking more about documentation in our next update.)

Our shop cat, Zener, has not actually helped out with production whatsoever. She did, however, manage to get her tail caught in the output roller of our (warm and tall) laser printer a couple of days ago, leading to a little down time while printing those booklets. (Cat is OK, less some fur. The printer is still recovering.)

And then, there’s final inspection. All the parts come together (with a giant checklist) in a padded carrying case with a reinforced handle.

The carrying case has a silkscreened cover. The metallic silver printing ink that we used for the first two batches looks really cool, but becomes invisible at a certain angle. So, we’re switching to an aqua blue for the next batch.

The completed WaterColorBot kits go in an outer shipping box, that keeps the carrying case safe for transport. It’s surprising how much of a warehouse you can fill with stacks of boxes!

WaterColorBot kits are shipping now, and we are still taking pre-orders for December shipment.