Tony writes in with a question about hacking our DIY LED matrix kits:

|

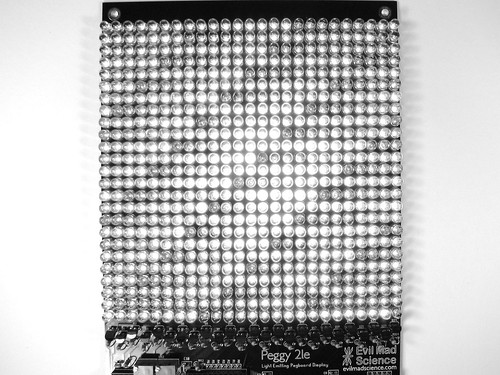

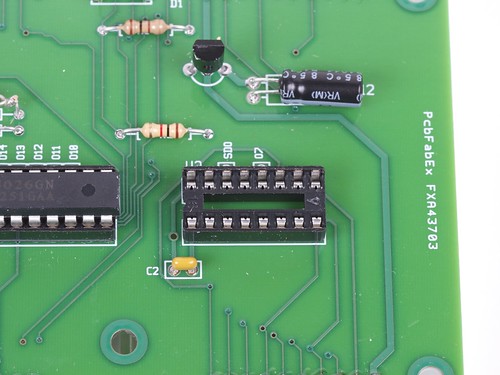

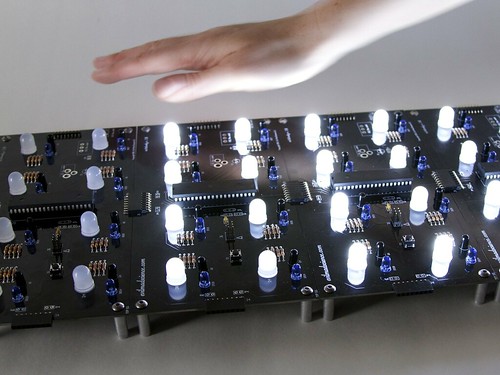

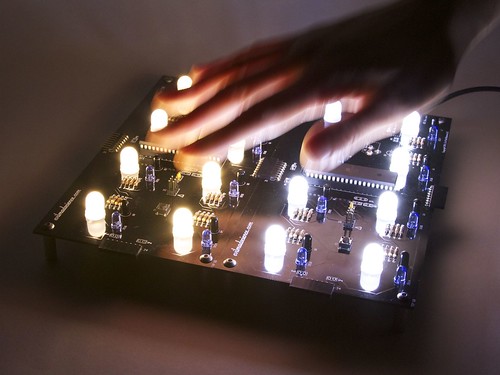

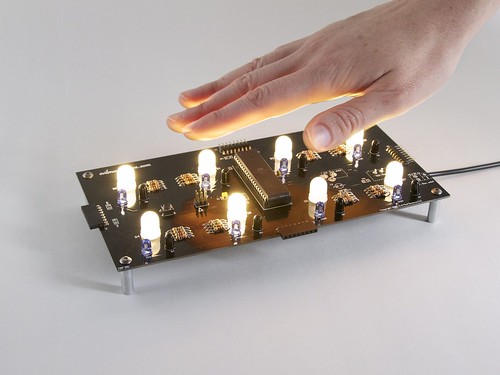

And, that’s actually an interesting topic. We’ve written before (here and here) about some giant-scale variations and modifications to our Peggy 2 and Peggy 2LE LED matrix kits, but we haven’t really addressed how one might go about building it.

First off, since you asked— and though we recommend against it —it is indeed possible to build an off-board LED matrix by simply running individual running wires from every LED location on the Peggy circuit board to every LED. There are 625 LEDs in a 25 × 25 grid, and if each has two wires… that turns out to be quite a few wires.

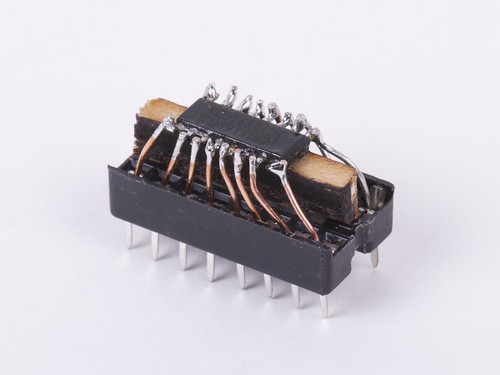

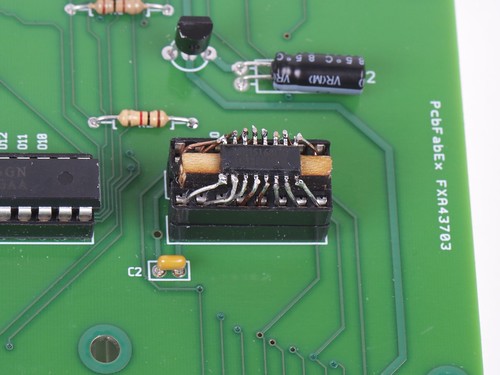

While *ahem* labor intensive, this method does work. We know this partly because several people have actually done it. The “rats nest” of thin, red-lacquered magnet wire shown above is one example, and the Peggy shown here is another victim example of this method.

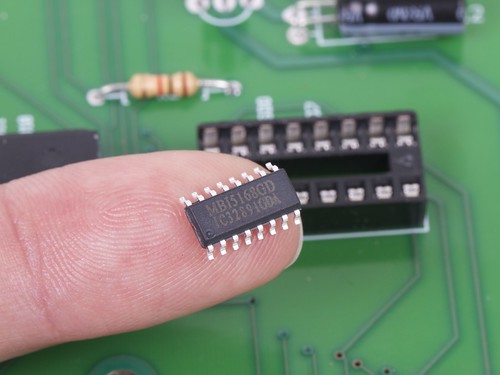

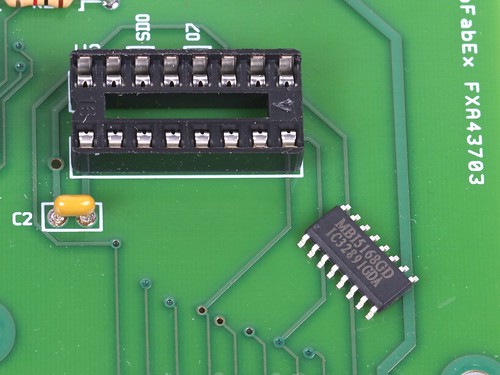

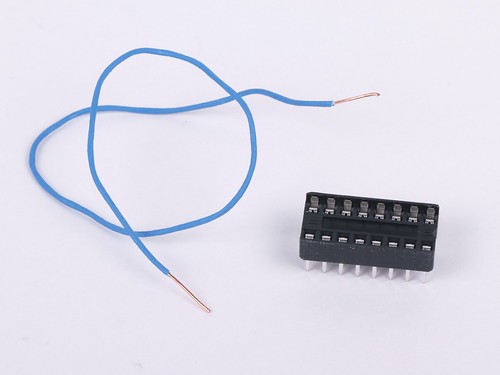

Fortunately, very fortunately, there are easier ways: think 50 wires, rather than 1250. And, there are a few other clever tricks that you might want to consider when changing the size of the matrix. For example, it’s possible to use the Peggy 2LE to drive an off-board LED matrix of size up to 25 × 32 without adding any other extra hardware.