This spring, I’ll be teaching several classes on Saturday afternoons at TechShop. TechShop is a San Francisco Bay Area “open-access public workshop,” located just off of 101 in Menlo Park, where you can go use a wide range of tools to make things. They have full-size milling machines and lathes, welding and rapid-prototyping equipment, Lego, sewing machines, computers, and well… just look at this list of equipment. (Seriously.)

One of the things that TechShop does is hold classes on a variety of topics. These are inexpensive (typically ~$30) drop-in classes that anyone can take without a long-term commitment. Many of them are short “safety and basic usage” classes that teach you what a given machine can do– and how to do it without killing yourself. Other classes teach simple and specialized skills like soldering for kids, blacksmithing, or silk screen printing. I’ll be teaching three (or four, depending how you count) classes, each of which will be held on a Saturday afternoon at Techshop.

Technical Graphics with POV-Ray

The first class is called “Technical Graphics with POV-Ray,” and is a hands-on workshop where you’ll learn how to use POV-Ray, a free cross-platform raytracing program that lets you make killer 3D graphics and animations. You can see some example images that I’ve made in POV-Ray (including the TechShop logo above) here, and master works in the POV-Ray hall of fame here. This is a two-part workshop with part 1 on 3/31/07, 1-3 PM, and part II on 4/7/07, also 1-3 PM.

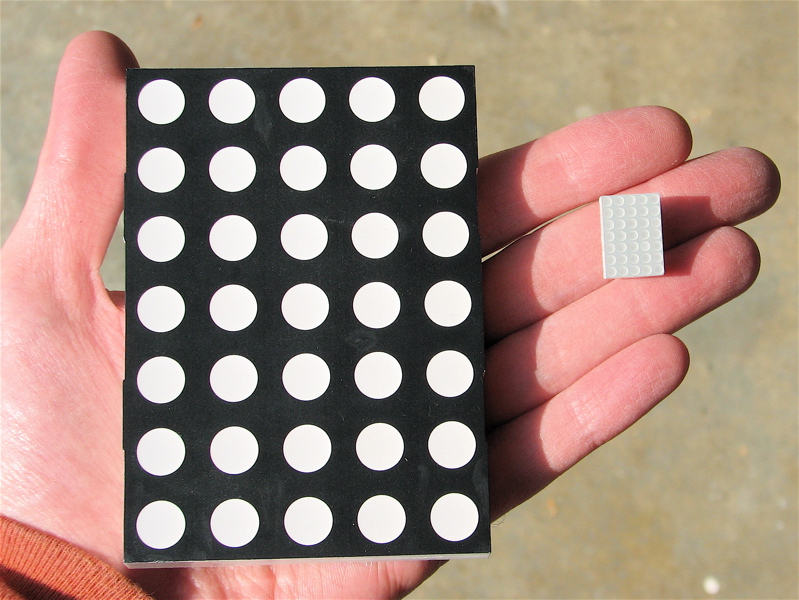

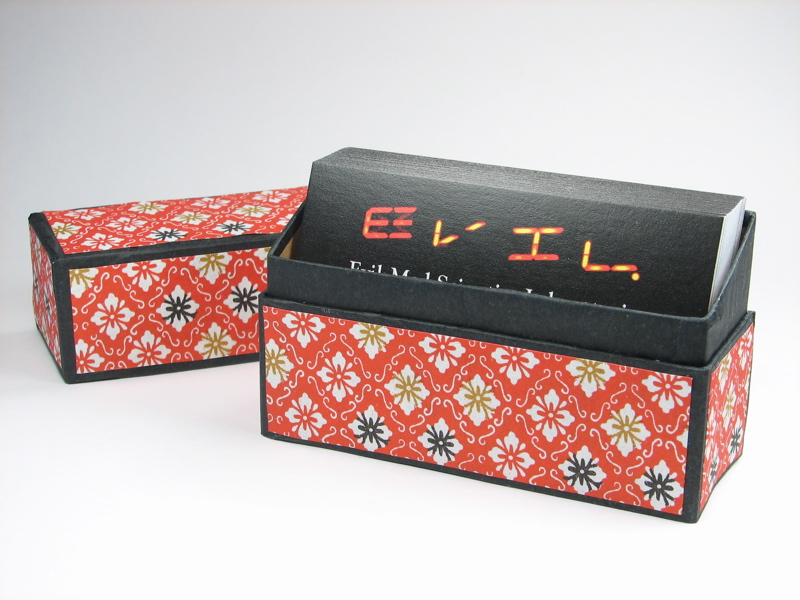

Make a custom LED Micro-Readerboard

On April 14, I’ll be teaching a little soldering class, suitable for anyone with a little bit of soldering experience (well, anyone whose age takes at least two digits to express in base-10 integers), where you can customize the phrases in and assemble an LED Micro-Readerboard, like the ones that we programmed to be ornaments a few months ago. But, since it’s not the holiday season, perhaps you want to make yours into an LED Micro-Readerboard Nametag instead!

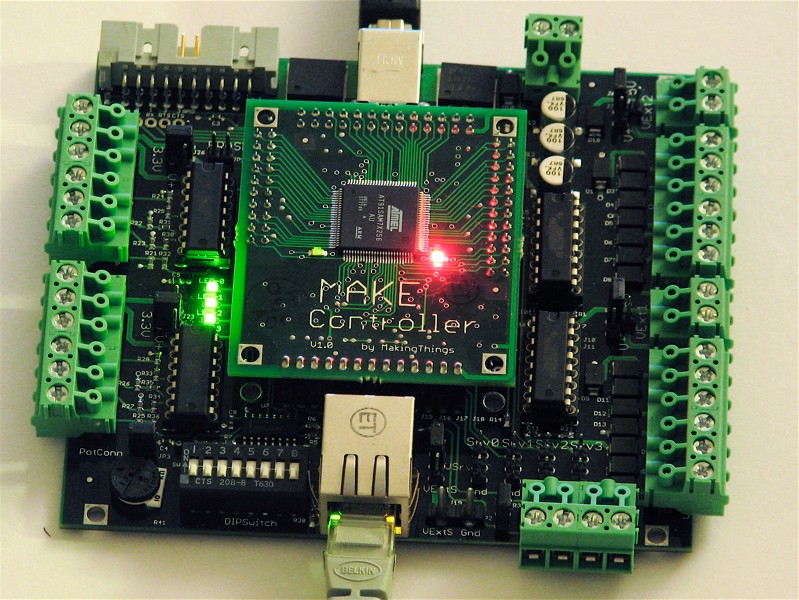

Choosing a microcontroller

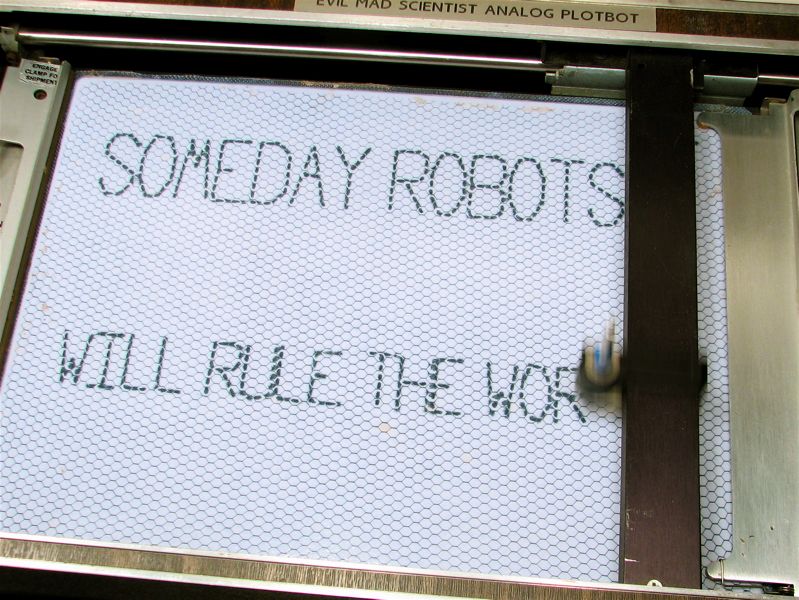

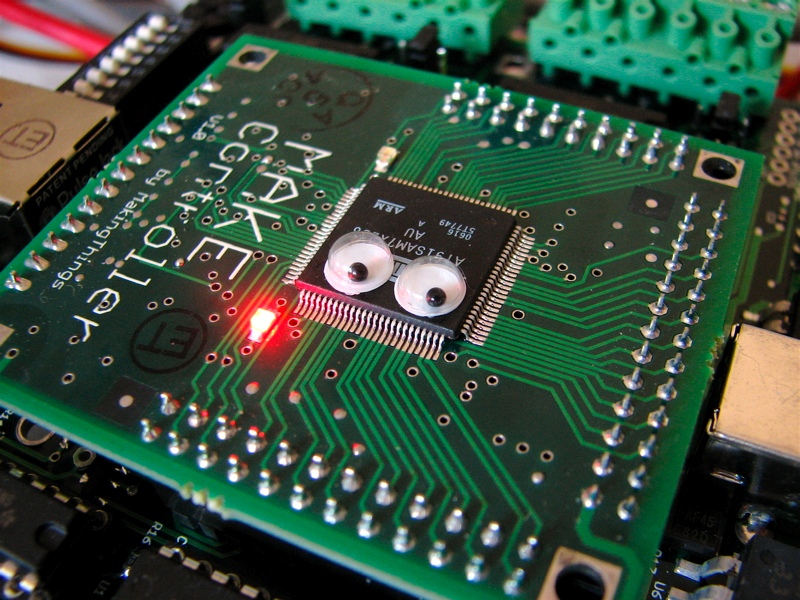

Finally, on April 21, I’ll be giving a large-format seminar that’s an introduction to microcontrollers, called Choosing a Microcontroller. This is designed to be an introduction to the capabilities and variety of single-chip computers, as well how to actually pick one for a given application. It’s easy to get overwhelmed looking at the variety of range of micros, from four-bit micros that have a 4-bit wide data path — and actually cost four bits— to AVRs and PICs, basic stamps and Arduinos, to 32-bit gorillas with names like ARM, Blackfin, and Coldfire. So, we’ll try and cut through the fog and help you figure out where to get started.

If you’ve heard people getting excited about or doing cool things with microcontrollers and want to learn more, this might be a great introduction to the field.

Sign up for these and other TechShop classes here. Sign up early, since space may be limited!

Also, if you have suggestions for other classes that you’d like to see taught by the Evil Mad Scientists, you can E-mail us or leave comments here.

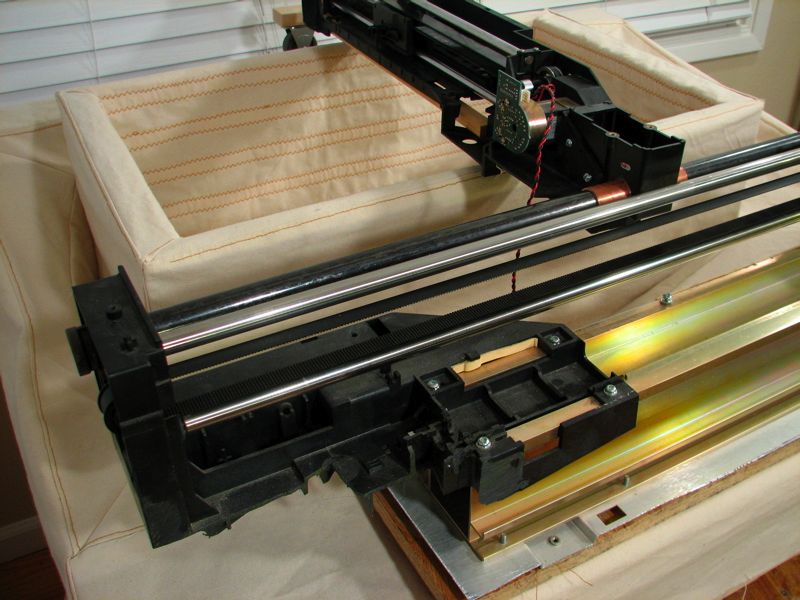

So you’ve got a microcontroller and you want to use it to control something analog. That’s a common task, and a number of good solutions exist, depending on exactly what you need to do.

So you’ve got a microcontroller and you want to use it to control something analog. That’s a common task, and a number of good solutions exist, depending on exactly what you need to do.